About us

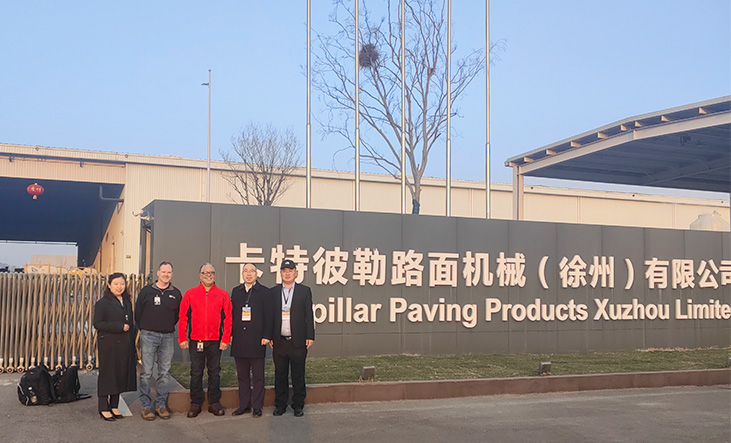

Focusing on the field of corrosion control!Qingdao Cortec Rust Proof Materials Co., Ltd.,

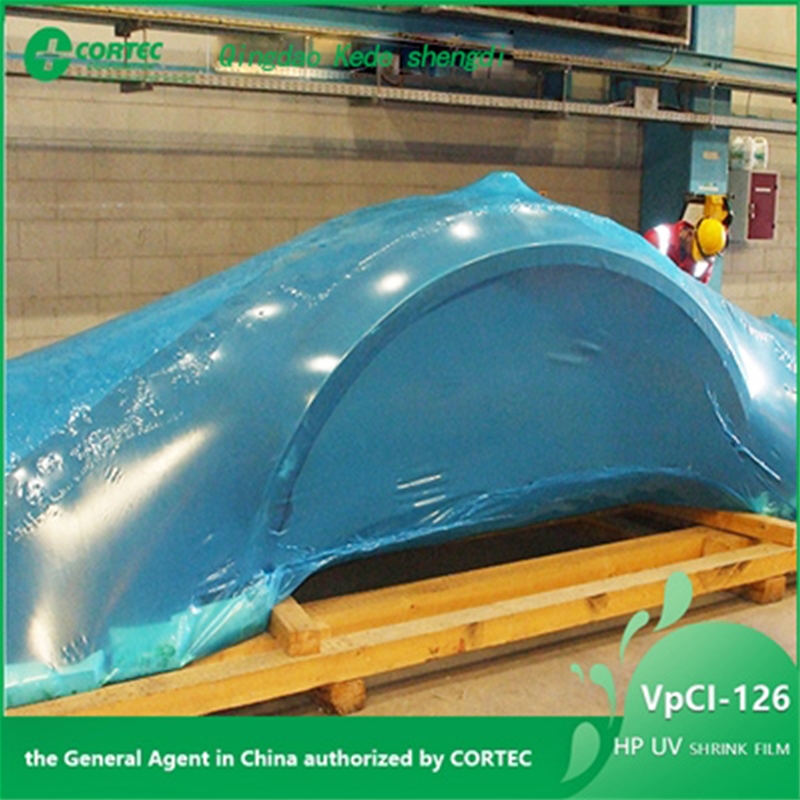

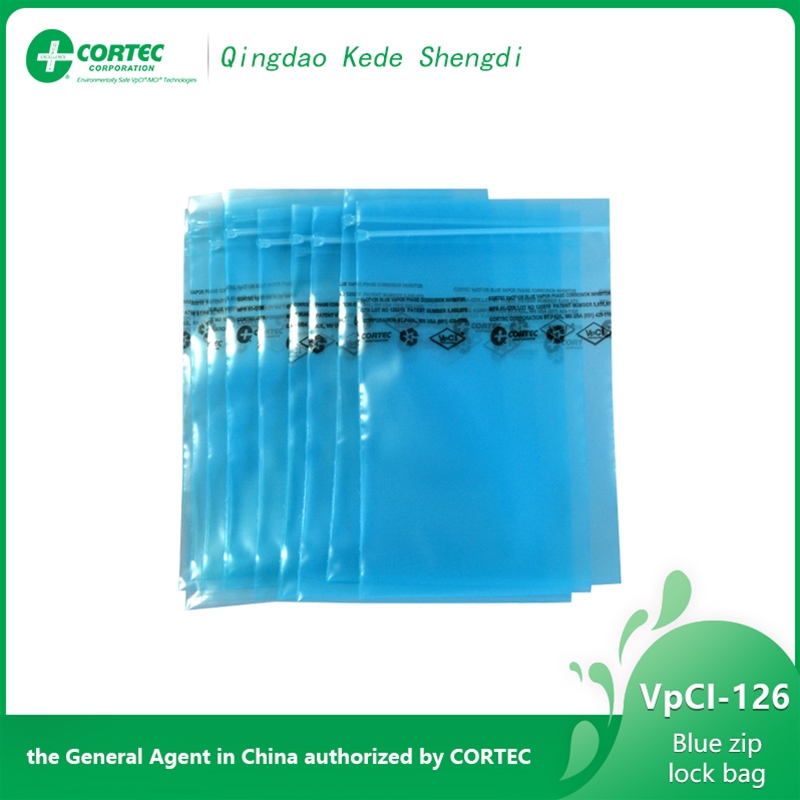

Qingdao Cortec Rust Proof Materials Co., Ltd., is authorized by the United States CORTEC corporation, China's exclusive distributor, our company's main products are VpCI (vapor phase) series of corrosion-proof products,including VpCI packaging (paper, film, shrink film, foam)...

MoreProduct Center

All products of the whole line are purchased at one stop- VpCI oils

- Water-based VpCI liquids

- Cleaner/Rust remover

- VpCI package

- Emitters

- VpCI powder

- VpCI additive

- VpCI coating

- VpCI foam

- Other products

- MCI (Migrating Corrosion Inhib...

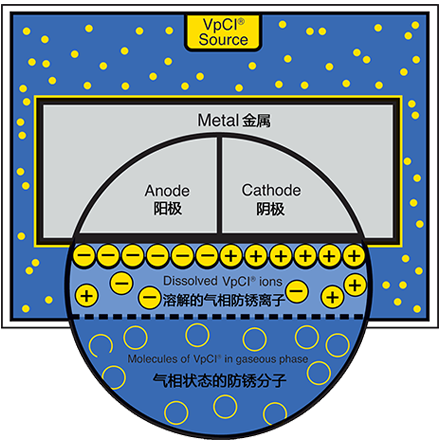

How VCI Works

How VCI Works

VCI is the generic term for “volatile corrosion inhibitor,” “vapor corrosion inhibitor,” or “Vapor phase Corrosion Inhibitor,” a revolutionary technology that simplifies corrosion protection and is ideal for keeping enclosed void spaces (e.g., packages, equipment internals, or structural metal cavities) rust-free. We have trademarked our Cortec® brand of VCIs under the name VpCI® to help ensure our customers are getting the premium VCI products that are trusted globally.

VCI technology works to create a protective environment within each package or enclosure where it is applied. VCIs inside liquids, powders, or packaging materials travel through the air to form an invisible protective shield on metal surfaces in the enclosed space. This VCI shield does not alter metal properties. Instead, it blocks the ability of oxygen, moisture, and other corrosive elements to attack the metal surface and make it rust. After the metal part is taken out of the VCI packaging or enclosed space, the VCIs float away, and the metal components, machinery, or products are ready for immediate use, no cleaning or degreasing required.

VCI technology works to create a protective environment within each package or enclosure where it is applied. VCIs inside liquids, powders, or packaging materials travel through the air to form an invisible protective shield on metal surfaces in the enclosed space. This VCI shield does not alter metal properties. Instead, it blocks the ability of oxygen, moisture, and other corrosive elements to attack the metal surface and make it rust. After the metal part is taken out of the VCI packaging or enclosed space, the VCIs float away, and the metal components, machinery, or products are ready for immediate use, no cleaning or degreasing required.

Industries application

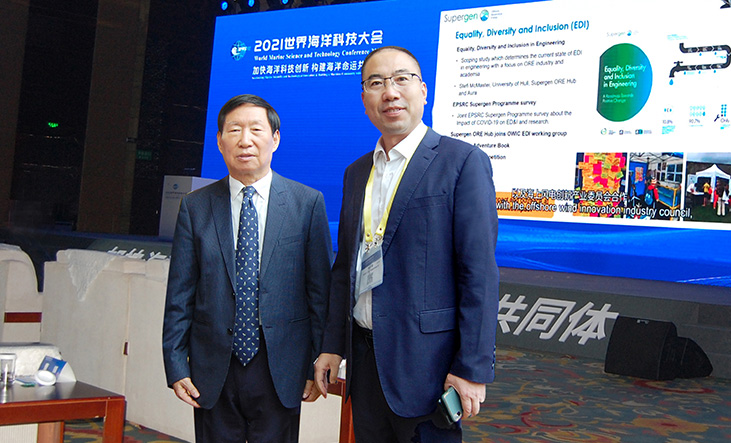

The product has a wide range of application fieldsEnterprise strength

China storage base of CORTEC all productsWhat’s new

Development is based on quality, success or failure are based on details.