VpCI package

ClassifyVpCI package

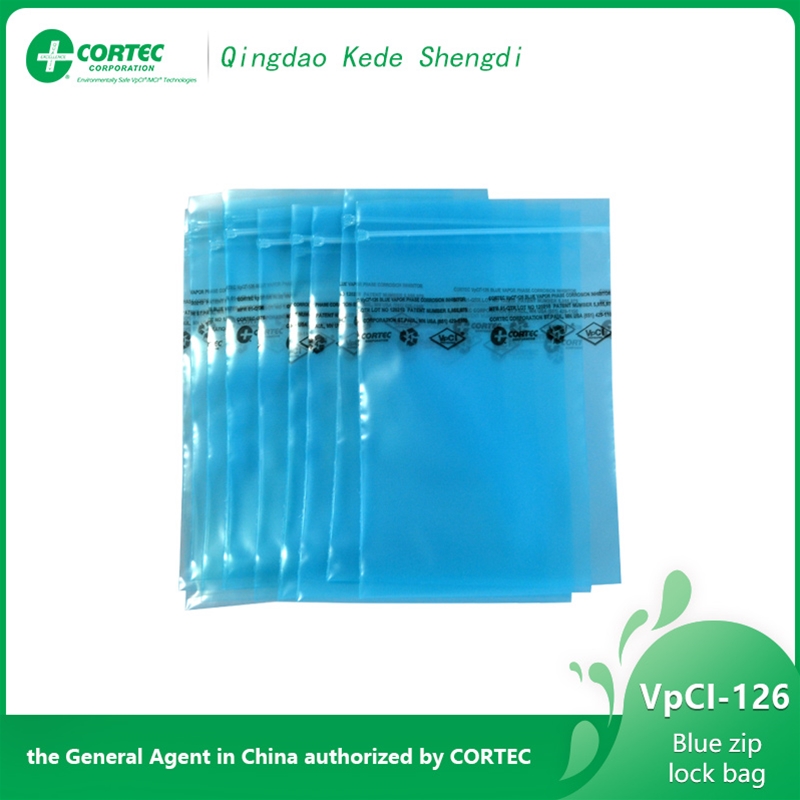

VpCI-126 Blue zip lock bag

PRODUCT DESCRIPTION:

Vapor phase Corrosion Inhibitor (VpCI®) 126 Series film combines the latest film technology with the most effective corrosion protection for all of your metal products. Sealing your product in Cortec® VpCI® films protects metal parts from all types of corrosion including rust, tarnish, stains, white rust, and oxidation for up to 5 years.* It’s as easy as putting your product in a Cortec® VpCI® package!

+86-0532-80989502,+86-135-0535-2885

E-Mail:zzgvci@163.com

Cortec® VpCI® films and bags replace conventional rust preventatives such as oils and desiccants. You save even more because VpCI® packaging eliminates the degreasing or coating removal required in the past. Now your product can be used immediately. VpCI®-126 is transparent, making it easy to identify parts. Additionally, it does not contain free amines, phosphates, or halogen-based materials, and is non-toxic and recyclable.

VpCI®-126 Series films and bags protect metal objects as small as a needle to as large as the contents of an oceangoing container.

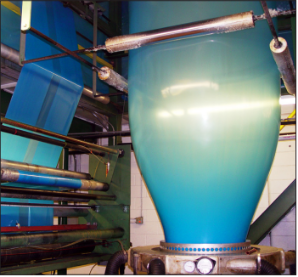

VpCI®-126 Blue can be manufactured utilizing a wide array of the most advanced resins. Custom blends are available to give you the exact properties you need, whether it’s improved puncture resistance, tear strength, or other requirements.

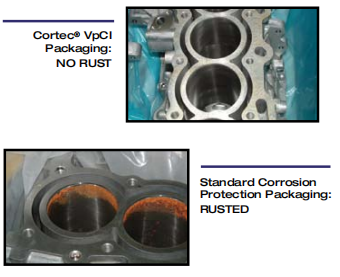

HIGH LEVEL OF CORROSION PROTECTION

Metal parts packaged in Cortec® VpCI®-126 Blue receive continuous protection against salt, excessive humidity, condensation, moisture, aggressive industrial atmospheres, and dissimilar metal corrosion. The VpCIs vaporize and then condense to metal surfaces in the enclosed package. VpCI® reaches every area of your part, protecting its exterior as well as hard-to-reach interior surfaces. You get complete product protection during storage as well as during domestic and overseas shipments, virtually eliminating any rust claims.

VpCI®-126 Series is the best selling anticorrosion PE film in the world today, with the highest level of corrosion protection demonstrated by standard and internal corrosion test methods. For further testing and case history information, please contact your Cortec® distributor or visit Cortec® at www.cortecvci.com.

RECYCLABLE & ENVIRONMENTALLY CONSCIOUS

Cortec® VpCI®-126 Blue has received approval from a leading institute regarding the recycling and disposal of packaging materials containing Cortec® proprietary chemistry.

Cortec® is committed to providing the most environmentally sustainable products in the industry. In addition to being fully recyclable, VpCI®-126 Blue film is typically made with 20% recycled content; further improving the environmental footprint of this product.

METALS PROTECTED

•Aluminum

•Galvanized Steel

•Carbon Steel

•Silicon Steel

Stainless Steel

•Copper

•Brass

•Cast Iron

SIZES AND CONSTRUCTIONS

Cortec® VpCI®-126 Blue is heat sealable and can be used with all types of manual or automated heat-seal packaging equipment. The material is available in a variety of standard and customized forms including bags, sheeting-reinforced film, top-seal and Auto-Bags, gusseted liners, bags-on-a-roll, perforated sheeting, coil covers, shrink film, and tubing to protect small or large parts. Antistatic (ESD) varieties are available as well as coextruded constructions. Opaque formulations are also available.

Cortec® VpCI® film is available in a variety of gauges ranging from 2 to 10 mils (50-250 microns) and widths from 3” to 32’ (7.6 cm

- 9.7 m).

TYPICAL MECHANICAL PROPERTIES

|

Property |

|

Test Method |

Units |

VpCI®-126 |

||

|

Thickness |

|

ASTM D6988 |

mil (μm) |

2.0 (50) |

4.0 (100) |

6.0 (150) |

|

Breaking Factor |

MD |

ASTM D882 |

lbs/in (N/m) |

9.3 (1629) |

18.4 (3226) |

18.9 (3306) |

|

TD |

9.5 (1665) |

18.7 (3277) |

18.3 (3196) |

|||

|

Tensile Strength at Break |

MD |

ASTM D882-02 |

psi (kPa) |

4759 (32.812) |

4424 (30.502) |

3184 (21.953) |

|

TD |

4603 (31.737) |

4357 (30.040) |

3110 (21.443) |

|||

|

Elongation at Break |

MD |

ASTM D882-02 |

% |

607 |

779 |

770.4 |

|

TD |

676.3 |

835 |

833.7 |

|||

|

Yield Strength |

MD |

ASTM D882-02 |

psi (kPa) |

1528 (15.535) |

1334 (9198) |

794 (5474) |

|

CD |

1576 (10.866) |

1610 (11.101) |

1425 (9825) |

|||

|

Tear Strength |

MD |

ASTM D1922-06a |

mN |

3755.3 |

11159.9 |

15853 |

|

CD |

7965.7 |

15413.5 |

20279.2 |

|||

|

Dart Drop Impact Resistance |

|

ASTM D1709-04, Test Method A |

grams |

347.4 |

790 |

753.3 |

PACKAGING AND STORAGE

To ensure best product performance, store in original packaging, indoors, and out of direct sunlight at 40-100 °F (4-38 °C).

Shelf life: 2 years

Previous:VpCI-126HP UV shrink film

Next:Cor-Pak Tablets

Qingdao Cortec Rust Proof Materials Co., Ltd.,

Consultation hotline:0532-80989502

Sales Hotline:135-0535-2885

E-mail:zzgvci@163.com

QQ:592192408

Address:Room 2073, No. 12, chongmingdao

East Road, Qingdao Economic Development Zone

Alibaba store:https://shop1420649126784.1688.com